Our control system is based on two basic concepts as a prerequisite for the high availability of the line: division of tasks and redundancy. Control hardware and software are designed on the basis of these principles.

Division of control tasks on several hardware system components increases the availability of the line in comparison to a monolithic system. Even the most sophisticated control is subject to an ongoing process of improvements or is frequently modified as permanent adaptation to the customers’ requirements, especially in the start-up phase. Division of control tasks on several components allows partial switching-off, partial updates and the exchange of system components without having to shut down the complete plant. Thus, line data are kept and time-consuming complete new starts can be avoided. Unavoidable interruptions of production can be reduced to an absolute minimum.

Redundancy in form of identical hardware multiply available in the system allows the distribution of tasks by switching the software during ongoing operation. Thus, operation can be kept running in all cases to virtually 100%. Further security measures are installed, e.g. transport equipment and other periphery is equipped with independent control units. Emergency actions and rescue operations can be executed even if control fails completely.

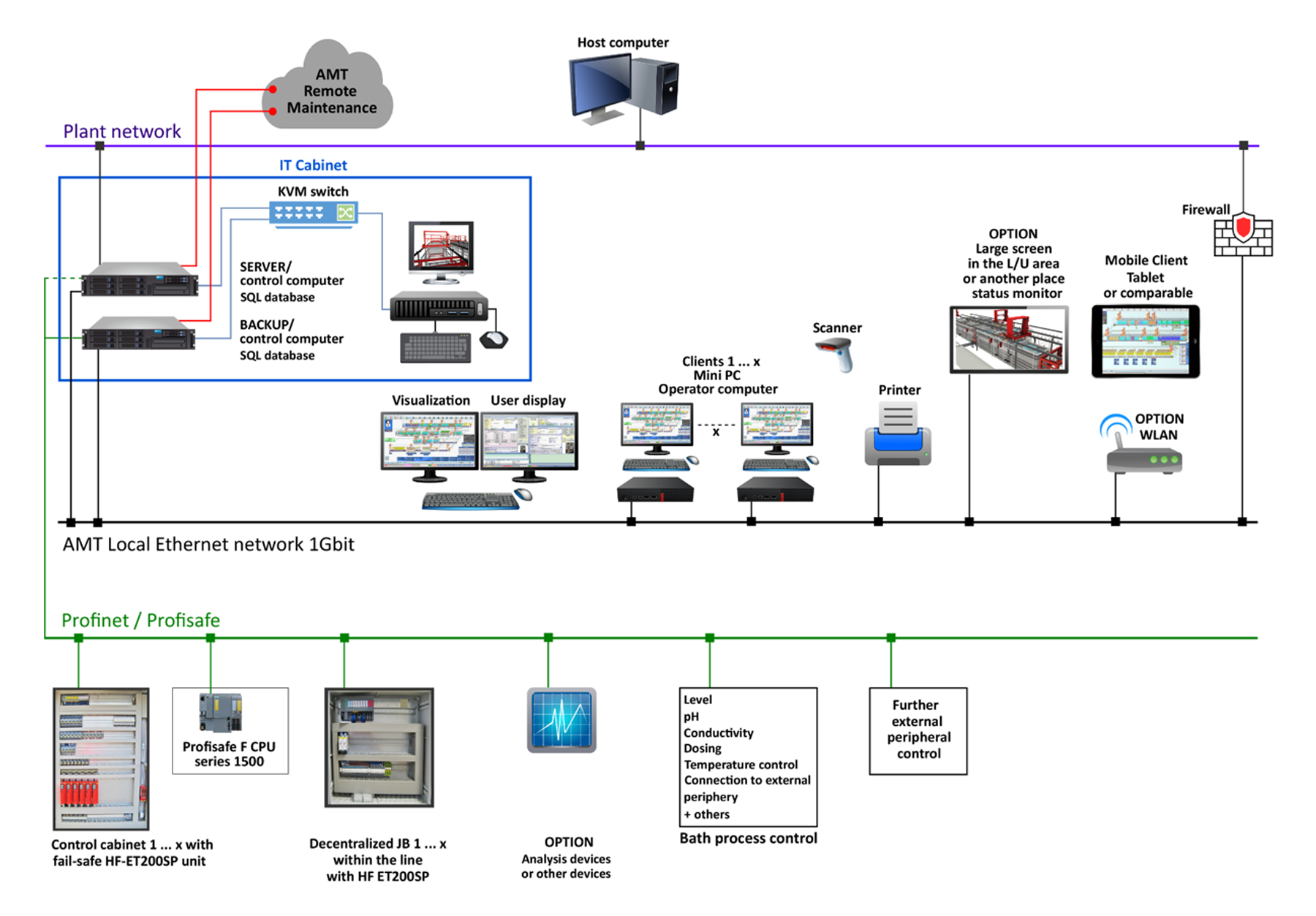

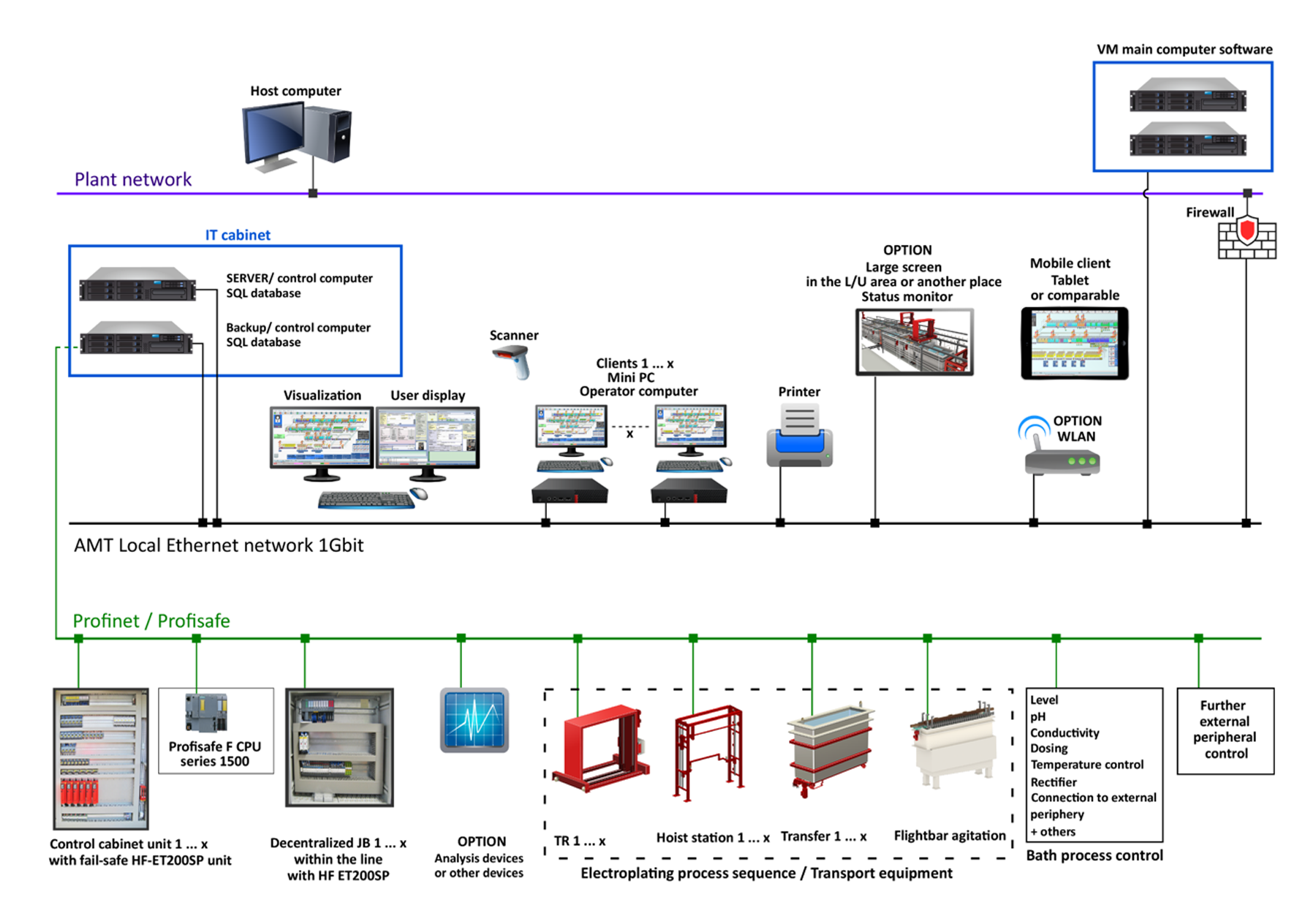

Structure of the HMI control system

Schematic structure of the HMI control system

Schematic structure of the HMI control system with virtualization

All the intended host computers, backup computers and the control periphery are plug-in computers with RAID system and redundant power supply units. A free PostgreSQL database is used. One server + one backup computer is used for redundancy and system security. If the server computer fails, the system automatically switches to the backup computer without any loss of data. If the peripheral control computer fails, the backup computer is also used for system control.

Mini PC client computers are the system’s operating computers, which can be used in any number on the loading / unloading stations or on other system positions.

The display and operating options of the mini PC client computers on the loading / unloading stations are 1:1 as on the server computer with the function and graphic display of the system image and all detailed individual screens without restriction. The applications of the mini PC client computers on the loading / unloading stations are normally limited to the individual masks, error messages etc. required on the loading / unloading station.

Freely definable information and status displays for the operators in the loading / unloading area can be issued at any time via external large screens. The large screens on the loading / unloading devices and within the system are optional and are not included in the scope of delivery.

The executable functions and displays within the client computer program can be freely parameterized for the respective applications from the main computer program. The system periphery is controlled by means of a peripheral control computer program, which works independently with a Siemens CP 1616 / CP 1626 ProfiNet interface module and establishes the connection to the external S7 ET200SP control modules or units.

The server backup computer, which is also equipped with a ProfiNet interface module, is used for fail-safe operation and redundancy. This does not reduce the computer performance required to run the control system in the backup function.

The entire system periphery is controlled and monitored in all control and regulation functions via the peripheral program and is effectively the PLC CPU of the control system. The control system is set up using freely parameterizable function blocks that are linked to the control sequence program. Definition and status can be viewed at any time. The textual designation of the function blocks is realized in the local language and easy to understand. The function blocks are provided in sufficient numbers with at least 20% reserve. Additional function blocks can be added at any time without any problems.